Under the extreme conditions of ultra-high / low pressure and ultra-high / low temperature, the properties and functions of the material after the overall compounding can be changed in a gradient.

Technical advantages

Dense structure of laser cladding, good wettability with substrate

High specific strength and specific stiffness, good fatigue resistance, high toughness and impact resistance, high electrical and thermal conductivity, good breakage safety, and good shock absorption performance

Simple and flexible forming process and good designability of material structure

By controlling the specific energy of the laser, the scanning speed and thickness of each layer of cladding, the cooling speed can be changed and the microstructure can be regulated.

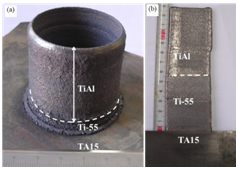

Different component combinations get different composite effects. Different parts of materials and structures have different performance properties

Stress caused by different thermophysical properties between different materials can be relieved.

The preparation of gradient materials by laser cladding is faster than the general process

Workpiece weight is reduced

Good air tightness

Innovation points

The application of gradient composites/structures can optimize the structure and materials, significantly improve the overall performance of systems and structures and the use efficiency of materials, and has important development prospects in aerospace and other fields. The preparation of gradient materials by laser cladding is faster than the general process.