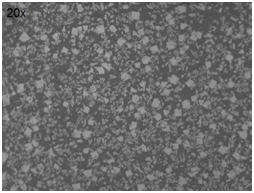

The bearing bush recovers and improves the performance of the workpiece successfully. The babbitt alloy has compact structure, excellent and stable performance, and is combined with the billet in 100% metallurgy.

With strong bearing capacity, good vibration resistance, high operating accuracy, stable operation, low noise, long life and other characteristics, sliding bearings are widely used in high-speed, heavy-load, high-precision, high-power equipment, which are the main components of automobile engines, industrial pumps, coal mills, steam turbines, nuclear power units, large and medium-sized electric motors, nuclear submarines, warships, and large ships, playing a vital role to ensure the normal operation in the large equipment. Among them, the bearing shell is a part of the sliding bearing that directly contacts the journal, and is subjected to large squeeze and friction during work. Frequent damages such as wear, scratches, gluing, fatigue peeling, and corrosion wear are common. The damage of the bearing shell will reduce the efficiency and affect the running safety of the sliding bearing. Therefore, we use laser cladding to repair the damaged bearing shell to achieve the hardness, wear resistance and other related performance parameters of the repaired bearing bush, which can reach or even exceed the re-cast bearing bush.

Technical advantages

Lower cost than re-cast the bearing shell

Low coating dilution rate

Improving wear-resistance of bearing shell

Short repair and construction period

Repairable to the inner surface of bearing shell

Fine and dense coating structure, combined with metallurgical substrate

Wide adjustable range of coating thickness, flexible process, easy to control and achieve automation

Selectable area for local processing

Innovation points

At present, there are not many companies that master bearing shell repair technology, and many companies’ technology of repairing the inside of the surface are not yet perfect.

|

|

|

|

|

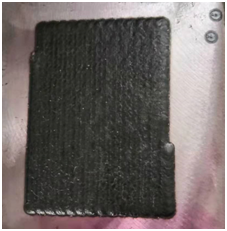

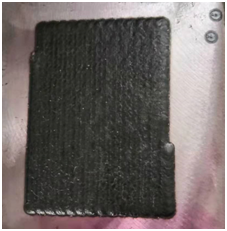

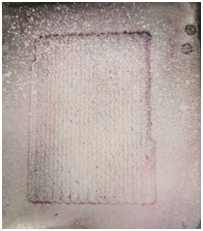

Laser cladding on the surface of steel billet to remanufacture Babbitt layer

|

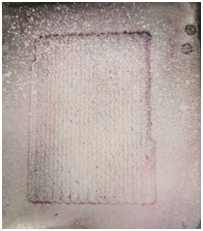

A flaw detection experiment of laser cladding bearing shell

|

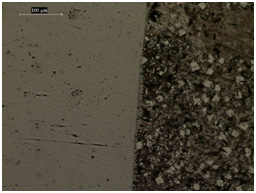

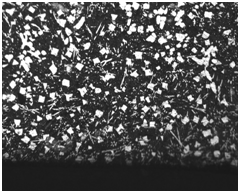

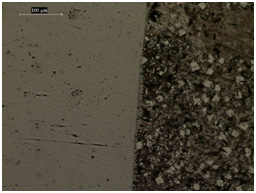

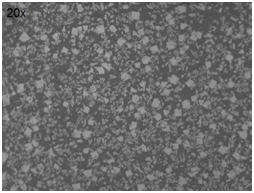

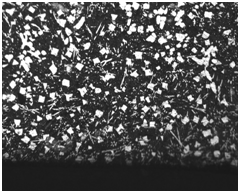

Metallographic diagram of laser cladding tin-based babbitt alloy

|

Babbitt metallography of cladding layer

|

Casting Babbitt metallography

|